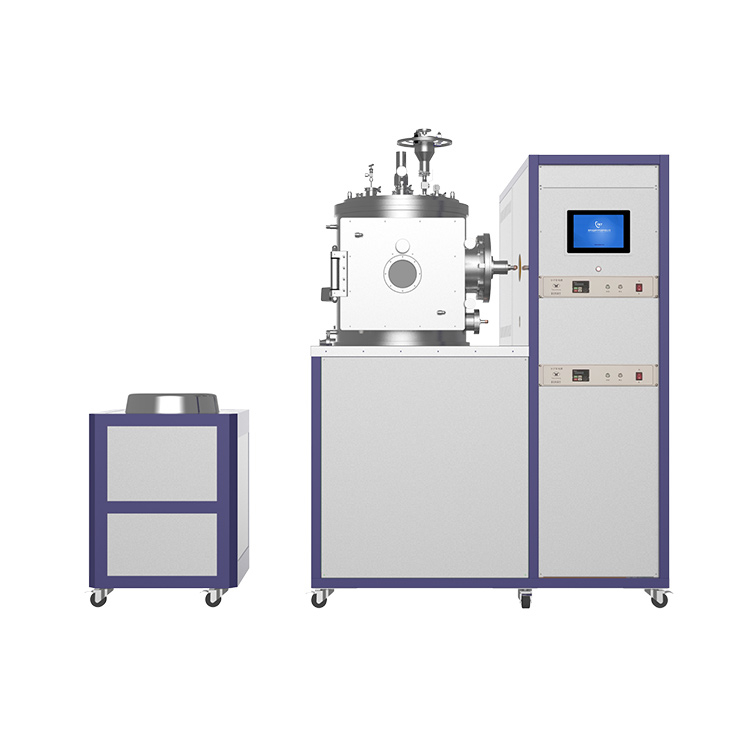

The directional solidification furnace is a new type of vacuum furnace that uses the principle of medium frequency induction heating to sinter high melting point metals, cemented carbide, silicon carbide ceramics and other materials under vacuum or protective atmosphere conditions. The equipment usually has a vertical furnace structure, including a furnace body, a heating sensor (graphite or resistance is selected as the heating element), a heating and insulation layer, a directional crystallizer and a mobile lifting mechanism, an operating platform, an inflation system, a power supply and a control system. Vacuum system and other components.

The working principle of the directional solidification furnace is to gradually solidify the material into a material with a specific crystal structure by controlling the temperature gradient and crystal growth rate. For example, a single crystal growth furnace is a directional solidification furnace used to produce single crystal materials, while a polycrystalline growth furnace is used to produce polycrystalline materials. These materials have different crystal structures and properties and are widely used in aerospace, optoelectronics, semiconductor, construction, automotive, electronics and other industries

Directional solidification furnace application scenarios:

Preparation of single crystal materials: Directional solidification furnaces, especially single crystal growth furnaces, are used to produce single crystal materials. Single crystal materials have excellent mechanical and electrical properties and are widely used in aerospace, optoelectronics, semiconductors and other fields.

Preparation of polycrystalline materials: The polycrystalline growth furnace is a directional solidification furnace for manufacturing polycrystalline materials. Polycrystalline materials are composed of multiple crystal grains, and there are grain boundaries between the grains. The grain boundaries have a certain impact on the properties of the material. Polycrystalline materials are widely used in construction, automobile, electronics and other industries.

Preparation of high-quality castings: The VIM series vacuum directional solidification furnace can produce high-quality castings with special structural structures such as turbine engine blades and gas turbine turbine blades. These castings have important applications in aerospace and other fields.

Annealing and brightening and degassing metals: Directional solidification furnaces can also be used to anneal, brighten and degassing metals to improve their properties and appearance.

Preparation of special materials: Depending on the structure and purpose, the directional solidification furnace can also be used to produce special materials such as single crystal or polycrystalline silicon, sintered ceramics or glass.

Technical parameters of directional solidification furnace:

Detailed technical parameters:

Vacuum induction melting furnace | product name | 2200℃ directional solidification furnace |

Product number | CY-IV500-25KW-SS-DX |

advantage | This equipment can be used as a directional solidification furnace or vacuum melting. When used as a vacuum melting furnace, you only need to cover the cooling pool. |

Bar thickness | Φ10mm、Φ20mm |

maximum heating temperature | 2200℃ |

Rated temperature | 2100℃ |

Heating element (tungsten, tantalum) inner diameter | Dia40×90mm |

High frequency heating power supply | Use power supply | High frequency heating power supply |

Oscillation frequency | 30-80KHZ |

Maximum input power | 25KW |

Heating current | 2-52A |

Cooling water requirements | ≥0.2MPa ≥6L/m |

Power supply weight | 35KG |

load duration | 100% |

Input voltage | Three-phase 380V 50 or 60HZ |

heating method | Induction heating |

Cavity inner diameter | 500mm |

Directional Solidification Crucible | Standard graphite |

Crucible protective cover | Zirconium quartz or aluminum oxide polycrystalline fiber or boron nitride protective sleeve |

Chamber vacuum (molecular pump unit) | < 6X10 -4Pa |

Chamber inflation pressure | < 0.05MPa |

Boost rate | <4Pa/s |

Burnout protection and display | yes |

Over temperature protection | yes |

Overcurrent protection | yes |

Under voltage protection (water pressure) | yes |

Temperature control mode | Smart PID |

control precision | ±1~ 5 ℃(600℃above) |

Temperature detection method | Imported infrared thermometer, temperature range 1000~3200℃ |

Technical solutions | A protective sleeve is placed on the induction coil, and the protective sleeve is wrapped with carbon felt to increase the thermal insulation performance. The inner side of the carbon felt is a layer of bright tantalum sheet, which can reflect heat back to the heating element. The inner side of the tantalum sheet is a tungsten heating element, and a crucible is placed in the heating element. The crucible is installed on the directional solidification rod. The heating element is heated by induction. There is a temperature gradient field between the heating element and the cooling pool. After the material in the crucible is heated and melted, it slowly descends with the directional solidification rod. The molten material drops evenly in this In the temperature gradient field, the crystal lattice rearranges and solidifies in a certain order, forming an ordered crystal. |

Directional solidification mechanism | Directional solidification stroke and speed can be controlled through the left touch screen, the speed range is 0.1μm/s~2000μm/s |

Can a water-cooled crucible be connected to the vacuum chamber? | ok |

Observation window size | Dia 90mm |

Vacuum unit | Unit input voltage | 380V /220V |

bellows | KF40X1000 |

Vacuum flapper valve | KF40 |

Front machine vacuum pump BSV30 | power | 0.75KW |

Voltage | 380V |

Rotating speed | 1450rpm |

Air intake diameter | KF25/KF40 |

Front pump pumping rate (L/S) | 8 |

ultimate pressure | 5X10 -1Pa |

Composite vacuum gauge | Composite vacuum gauge model | ZDF |

power supply | 220V 55W |

control precision | ± 1% |

Vacuum gauge measuring range | 10-5 -10 5 Pa |

Secondary pump for molecular pumps (Option One) | Molecular pump (The vacuum degree of the cavity can be pumped to 6X10E-4Pa) | Molecular pump model | FJ620 |

Input voltage | 220V |

Molecular pump air inlet flange | DN160 |

Molecular pump pumping rate L/S (to air) | 600 |

Molecular pump ultimate pressure (Pa) | 6×10-7 |

cooling method | water cooling |

Cooling water pressure (MPa) | 0.1-0.2 |

Cooling water temperature | <25℃ |

ambient temperature | 0~40℃ |

Recommended starting pressure | <10Pa |

| The secondary pump is a diffusion pump (Option II) | diffusion pump The vacuum degree of the cavity can be pumped to 5X10E-3Pa) | Voltage | 220V |

power | 1000W |

Ultimate vacuum degree (when there is no leakage) | 10E-5Pa |

Air intake interface | DN150 |

Air outlet interface | DN40 |

Amount of oil injected | 0.3L |

Pumping rate (N2) | 1000L/S |

Water cooler (optional) | power supply | 3PH-380V/50HZ |

Maximum lift | 40M |

Maximum flow | 16L/min |

Water tank capacity | 60L |

Refrigeration capacity | 103Kcal/h |

water inlet and outlet | Rp1/2’’ |

Machine size | 1150×520×1145(LXXXH) |